Biofouling in cooling tower systems is worldwide, multi-billion-dollar problem. Biofilm is the primary cause or a chief contributor to the following cooling tower system complications.

Biofilm Formation

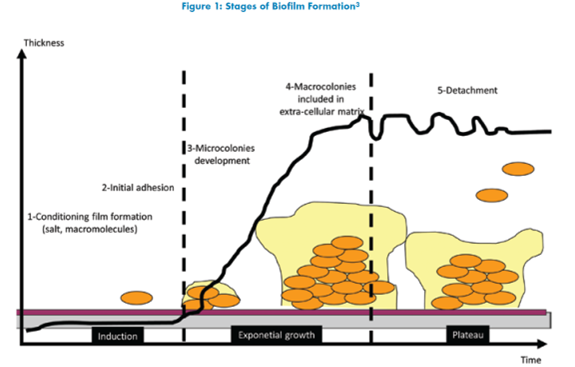

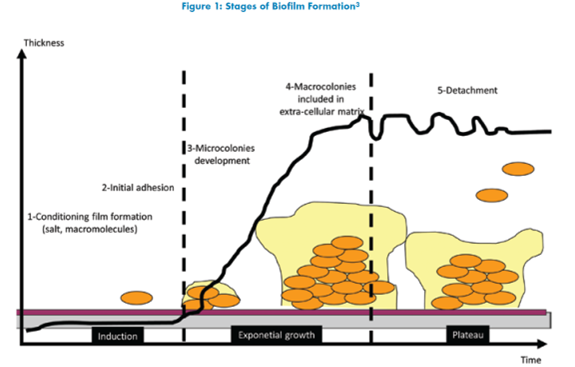

Biofilm is a consortium of microbial life and cooling towers act as complex ecosystems where bacteria and other organisms can thrive and safely multiply. Biofilm formation occurs in multiple distinct steps as shown in Figure 1. This process begins with the formation of a conditioning film onto which planktonic microorganisms will attach, multiply and eventually form a sessile colony. Salts and macromolecules present in the water absorb onto the pipe walls or other systems surfaces. Next, one or more pioneering microorganisms will come in contact with the conditioning film vial local hydrodynamics or swimming and then adhere to the conditioned surface. This initial adhesion is reversible if the pioneering microorganisms find that the conditioning film does not provide a suitable environment for colonization. If the microorganisms find the film to be a hospitable location, they will produce a glue-like exopolysaccharide and form an attachment that is irreversible without external influence. At this point, the microorganisms will reproduce at an exponential rate, leading to proper biofilm development on the substrate. As the resulting biofilm matures, certain specimens may detach from the colony in search of a new colonization site elsewhere in the system. The propagation of biofilm continues through a repeating cycle of adherence, growth and detachment.

Biofilm is a consortium of microbial life and cooling towers act as complex ecosystems where bacteria and other organisms can thrive and safely multiply. Biofilm formation occurs in multiple distinct steps as shown in Figure 1. This process begins with the formation of a conditioning film onto which planktonic microorganisms will attach, multiply and eventually form a sessile colony. Salts and macromolecules present in the water absorb onto the pipe walls or other systems surfaces. Next, one or more pioneering microorganisms will come in contact with the conditioning film vial local hydrodynamics or swimming and then adhere to the conditioned surface. This initial adhesion is reversible if the pioneering microorganisms find that the conditioning film does not provide a suitable environment for colonization. If the microorganisms find the film to be a hospitable location, they will produce a glue-like exopolysaccharide and form an attachment that is irreversible without external influence. At this point, the microorganisms will reproduce at an exponential rate, leading to proper biofilm development on the substrate. As the resulting biofilm matures, certain specimens may detach from the colony in search of a new colonization site elsewhere in the system. The propagation of biofilm continues through a repeating cycle of adherence, growth and detachment.

Heat Transfer Inefficiency

Biofilms forms an insulative layer in system piping and heat exchangers, creating a barrier between recirculating cooling water and heat exchange surfaces. Biofilm carries more than four times the insulating capacity of calcium carbonate scale. Additionally, biofilms in pipes and heat exchangers create frictional resistance to recirculation water, resulting in increases in the power required to operate recirculating pumps. The California Society for Healthcare Engineering estimates that a layer of biofilm measuring just 150 microns in thickness will result in a 5.3% increase in energy consumption in cooling tower systems, while a biofilm measuring 900 microns in thickness will result in a 32.2% increase.

Microbiologically Influenced Corrosion

Biofilms can harbor a variety of bacteria including anaerobic sulfate-reducing bacteria (SRB). SRB obtain oxygen by reducing sulfate and produce hydrogen sulfide as a byproduct. Hydrogen sulfide disassociates in water to forms weak acid, which corrodes the underlying metal to which SRB are attached. This process of microbiologically influenced corrosion (MIC) is known to create pits with localized corrosion rates up to 100 mils per year. If left untreated, MIC can penetrate completely through metal surfaces at an alarming rate. It is estimated that 205 of all damage attributed to corrosion in fluid systems is microbiologically influenced.

Scale Formation

As biofilms grow on heat exchange surfaces, the carboxylate groups present in the extracellular polysaccharide matrix can attract scale-forming cations such as calcium. The biofilm acts as a binding agent for these minerals, resulting in an even more robust biofilm with calcium fixed close to the heat exchange surface. This altered surface structure can attract seed crystals in the bulk water, which promote the formation of mineral scales.

Legionnaires’ Disease

Much attention and countless resources have been devoted to the study, treatment and prevention of disease caused by bacteria present in potable water and evaporative cooling tower systems. It has been reported that up to 18,000 cases of Legionnaires’ Disease are reported each year in the U.S. alone. The physical debilitation and loss of life associated with bacteria bred in biofilm make this one of the more troubling cooling tower systems concerns.

Biofilm is a consortium of microbial life and cooling towers act as complex ecosystems where bacteria and other organisms can thrive and safely multiply. Biofilm formation occurs in multiple distinct steps as shown in Figure 1. This process begins with the formation of a conditioning film onto which planktonic microorganisms will attach, multiply and eventually form a sessile colony. Salts and macromolecules present in the water absorb onto the pipe walls or other systems surfaces. Next, one or more pioneering microorganisms will come in contact with the conditioning film vial local hydrodynamics or swimming and then adhere to the conditioned surface. This initial adhesion is reversible if the pioneering microorganisms find that the conditioning film does not provide a suitable environment for colonization. If the microorganisms find the film to be a hospitable location, they will produce a glue-like exopolysaccharide and form an attachment that is irreversible without external influence. At this point, the microorganisms will reproduce at an exponential rate, leading to proper biofilm development on the substrate. As the resulting biofilm matures, certain specimens may detach from the colony in search of a new colonization site elsewhere in the system. The propagation of biofilm continues through a repeating cycle of adherence, growth and detachment.

Biofilm is a consortium of microbial life and cooling towers act as complex ecosystems where bacteria and other organisms can thrive and safely multiply. Biofilm formation occurs in multiple distinct steps as shown in Figure 1. This process begins with the formation of a conditioning film onto which planktonic microorganisms will attach, multiply and eventually form a sessile colony. Salts and macromolecules present in the water absorb onto the pipe walls or other systems surfaces. Next, one or more pioneering microorganisms will come in contact with the conditioning film vial local hydrodynamics or swimming and then adhere to the conditioned surface. This initial adhesion is reversible if the pioneering microorganisms find that the conditioning film does not provide a suitable environment for colonization. If the microorganisms find the film to be a hospitable location, they will produce a glue-like exopolysaccharide and form an attachment that is irreversible without external influence. At this point, the microorganisms will reproduce at an exponential rate, leading to proper biofilm development on the substrate. As the resulting biofilm matures, certain specimens may detach from the colony in search of a new colonization site elsewhere in the system. The propagation of biofilm continues through a repeating cycle of adherence, growth and detachment. Testing for microbial activity is an effective way to monitor the level of biofouling in a system.

Testing for microbial activity is an effective way to monitor the level of biofouling in a system.