Innovational Water Solutions’ air intake filtration screens are engineered to use on cooling towers, condenser coils, and other HVAC equipment. They are designed to prevent the fouling of your equipment. Naturally occurring airborne contaminants like seeds, insects, leaves, and other debris are stopped before they enter your system. Cleaning the screens is simple; use a broom, brush, shop vacuum, or even rinse with a garden hose.

Over 95% of debris entering cooling towers comes in through the intake opening! Cottonwood Filter Screens will stop that debris at its point of entry and protect the fill, sump, blow-down valves and heat exchangers from airborne debris, ensuring optimal cooling efficiency year around. Configurations are also available for RTU’s, AHU’s, Chillers, Dry Coolers, Louvers and more.

Keeping up with HVAC maintenance can be a full-time job for most production operations. IWS Air Intake Filter Screens are specifically engineered for use on condenser coils, cooling towers and other HVAC equipment, and is the best way to prevent fouling of your equipment.

IWS Air Intake Filter Screens are custom made and designed to mount to the outside of equipment. Window screens, bug screens, shade screens and filters such as, roll media, pleated or electrostatic filters, are many times less efficient and harder to use. The IWS Air Intake Filter Screen can be easily seen and quickly cleaned using a broom, brush, shop vacuum or by simply rinsing with a garden hose. No need to remove for cleaning, and even rain has a cleansing effect.

IWS Air Intake Filter Screens are custom made and designed to mount to the outside of equipment. Window screens, bug screens, shade screens and filters such as, roll media, pleated or electrostatic filters, are many times less efficient and harder to use. The IWS Air Intake Filter Screen can be easily seen and quickly cleaned using a broom, brush, shop vacuum or by simply rinsing with a garden hose. No need to remove for cleaning, and even rain has a cleansing effect.

Equipment disassembly, then cleaning with power washers, solvent hoses, and other cleaning accessories that need to be assembled and moved to rooftops, and other out of the way locations will longer be necessary.

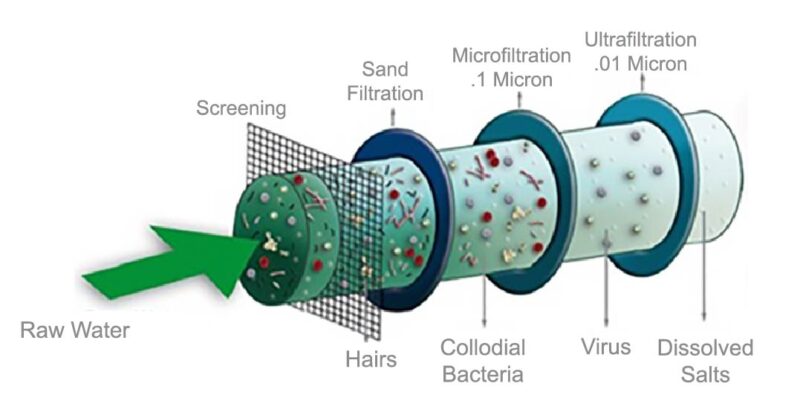

Our Reverse Osmosis Systems are designed for overall superior performance, high recovery rates, minimal energy consumption and offer great savings with low maintenance and operation costs.

Our Reverse Osmosis Systems are designed for overall superior performance, high recovery rates, minimal energy consumption and offer great savings with low maintenance and operation costs.