Our products and services are designed to provide corrective action plans based on analytical testing of inhibitor levels & efficacy, system corrosion, and glycol freeze protection in your hydronic system.

The solid treatment products we offer include closed loop treatments, closed loop cleaners, and closed systems cleaners/passivators.

Hydronic Heat Transfer Systems, Closed Hydronic Systems, Closed Loops are often neglected components of a heating/cooling system. Many facilities do not have a maintenance program for their Closed Systems. Iws believes that regular maintenance is important to keep the system clean, protected and running efficiently.

A neglected closed hydronic system is at risk for corrosion. System water with low pH or dissolved gases such as oxygen or carbon dioxide can cause corrosion. Microbiological growth and/or deposits of particulate matter (under deposit corrosion) can also cause corrosion.

Erosion corrosion occurs as particulate circulates through the system. It erodes piping and as it erodes it creates more particulate. The amount of particulates continue to grow and erode away piping until there is a leak. Treatment will create a passivating layer that can protect piping but it must be maintained at the proper level.

Fouling can occur when there is a build-up of particulate matter from pipe/ equipment material corrosion and microbiological growth. Debris not removed during initial construction or when new piping/equipment is added to the system can also foul systems. On new systems or new additions, installers/contractors often leave dirt, oils, grease and other matter in the piping. Flushing the system with water does not always remove the debris/dirt/grease. The debris/dirt/grease can travel through the system and deposit on the coils, heat exchangers and other heat transfer surfaces.

Regular maintenance should start when the system is new or when additions are made to the system. A proper cleaning should be done prior to the system start up. Continuing system maintenance should include monitoring the treatment levels to keep your system protected from corrosion and fouling.

Innovational Water Solutions will survey your system and analyze the system to find any weaknesses or issues that could be affecting the efficiency of the system. We will make recommendations to correct any current issues and make suggestions to keep your system clean, protected and running at peak efficiency.

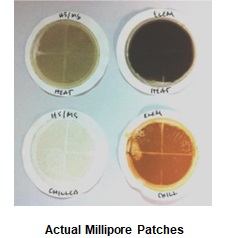

A Corrosion Study is an analysis that monitors the conditions of chilled, heating, dual or geothermal hydronic systems. Corrosion Studies present a clear measurement of system cleanliness, inhibitor effectiveness, inhibitor level, glycol level, and active corrosion in the system. Millipore patches provided a visual of the system conditions.

A Corrosion Study is an analysis that monitors the conditions of chilled, heating, dual or geothermal hydronic systems. Corrosion Studies present a clear measurement of system cleanliness, inhibitor effectiveness, inhibitor level, glycol level, and active corrosion in the system. Millipore patches provided a visual of the system conditions.